How are neodymium iron boron magnets used in the automotive industry?

Neodymium iron boron (NdFeB) magnets are widely used in the automotive industry for various applications due to their high magnetic strength and compact size. Here are some ways in which neodymium iron boron magnets are used in the automotive industry:

Electric Motors: NdFeB magnets are utilized in electric vehicle (EV) motors and hybrid vehicle motors. Their strong magnetic properties contribute to high torque generation and improved motor efficiency, enabling efficient propulsion of electric and hybrid vehicles.

Power Steering Systems: Neodymium iron boron magnets are employed in electric power steering (EPS) systems. They assist in providing the necessary torque for steering control, allowing for precise and responsive steering in vehicles.

Electric Braking Systems: NdFeB magnets are used in electric braking systems, such as regenerative braking systems found in electric and hybrid vehicles. They help convert kinetic energy into electrical energy during braking, enabling energy recovery and improving overall vehicle efficiency.

Starters and Alternators: Neodymium iron boron magnets are used in vehicle starters and alternators. They contribute to the compact size and high efficiency of these components, aiding in the starting of internal combustion engines and generating electrical power for various vehicle systems.

Electric Door Locks and Windows: NdFeB magnets are employed in electric door lock systems and power windows. Their strong magnetic force facilitates secure and efficient locking mechanisms, as well as smooth operation of power windows.

Sensors and Switches: Neodymium iron boron magnets are used in various automotive sensors and switches, such as wheel speed sensors, throttle position sensors, and position switches. They enable accurate detection, monitoring, and control of vehicle systems and components.

Anti-lock Braking Systems (ABS): NdFeB magnets play a role in anti-lock braking systems. They are utilized in speed sensors to detect wheel speed and provide information for ABS operation, contributing to safer and more effective braking in vehicles.

Suspension Systems: Neodymium iron boron magnets can be incorporated into suspension systems for active damping control. They assist in adjusting the suspension dynamics to improve vehicle stability, comfort, and handling.

What role do neodymium iron boron magnets play in renewable energy technologies?

Neodymium iron boron (NdFeB) magnets play a crucial role in various renewable energy technologies, primarily in wind turbines and electric generators. Here are the key roles of NdFeB magnets in renewable energy:

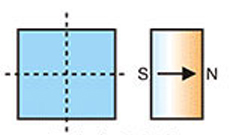

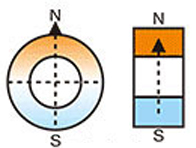

Wind Turbines: NdFeB magnets are used in the generators of wind turbines. They are typically found in the rotor, where the rotational motion of the blades is converted into electrical energy. The strong magnetic properties of NdFeB magnets enable efficient power generation by converting the mechanical energy of the wind into electrical energy.

Electric Generators: NdFeB magnets are employed in electric generators used in various renewable energy systems, such as hydroelectric power plants and tidal power generation. They help convert mechanical energy, derived from water flow or tides, into electrical energy.

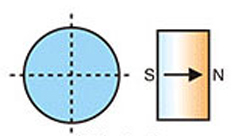

Direct-Drive Systems: NdFeB magnets are utilized in direct-drive systems, where the turbine rotor is directly connected to the generator without the need for a gearbox. These systems are preferred for their simplicity, reduced maintenance, and improved efficiency. NdFeB magnets provide the necessary magnetic force for direct-drive generators, resulting in compact and efficient power generation systems.

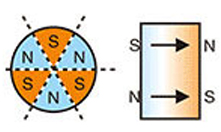

Efficiency Improvement: The use of NdFeB magnets in renewable energy technologies significantly enhances the efficiency of power generation. Their strong magnetic properties enable generators to operate at higher speeds and produce more electricity per unit of mechanical input, increasing overall energy conversion efficiency.

Size and Weight Reduction: NdFeB magnets allow for the design of more compact and lightweight renewable energy systems. Their high magnetic strength allows for smaller generator sizes, which is particularly beneficial for offshore wind turbines or other space-constrained applications.

英语

英语 日语

日语 德语

德语