What are the different types of permanent magnet components?

There are several different types of permanent magnet components, each with its unique characteristics and applications. Here are some of the commonly used types:

Permanent Magnet Discs/Cylinders: These are cylindrical or disc-shaped magnets with equal diameter and height. They are widely used in motors, generators, sensors, and various industrial applications.

Permanent Magnet Blocks/Rectangles: Block-shaped or rectangular magnets have a rectangular cross-section with varying lengths, widths, and thicknesses. They are often utilized in magnetic assemblies, magnetic separators, magnetic chucks, and magnetic lifting devices.

Permanent Magnet Rings/Toroids: Ring-shaped or toroidal magnets have a circular or annular geometry. They are commonly used in motors, magnetic couplings, loudspeakers, and other applications where a circular magnetic field is required.

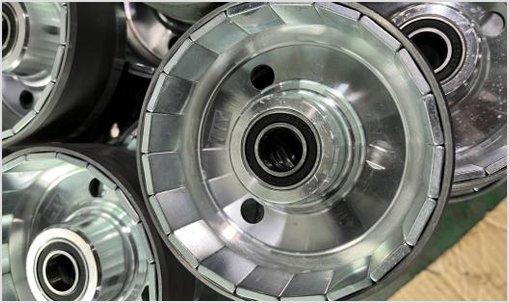

Permanent Magnet Arcs/Segments: Arc-shaped or segment magnets have a curved geometry, resembling a portion of a ring or cylinder. They are used in motors, generators, magnetic separators, and applications requiring specific arc shapes for optimal magnetic performance.

Permanent Magnet Spheres/Balls: Spherical magnets are utilized in various applications such as magnetic toys, educational kits, magnetic levitation, and artistic displays. They can also be incorporated into medical devices and magnetic resonance imaging (MRI) systems.

Permanent Magnet Custom Shapes: Permanent magnets can be custom manufactured in specific shapes to meet unique application requirements. These custom shapes can vary widely and are designed to fit specific dimensions and magnetic field requirements.

What are the factors to consider when selecting permanent magnet components for a particular application?

When selecting permanent magnet components for a specific application, several factors need to be considered to ensure optimal performance and suitability. Here are some important factors to consider:

Magnetic Properties: Evaluate the required magnetic properties of the magnet, such as magnetic field strength, magnetic energy product, coercivity, and temperature stability. The magnet should have properties that align with the application's needs, including desired magnetic field strength, stability under operating conditions, and resistance to demagnetization.

Operating Environment: Consider the environmental conditions in which the magnet will operate, including temperature, humidity, exposure to chemicals, and mechanical stress. Some magnets may be more suitable for high-temperature environments, while others may have better corrosion resistance or mechanical durability.

Size and Shape: Determine the appropriate size and shape of the magnet that will fit within the available space and align with the design requirements of the application. Consider factors such as magnet dimensions, weight, and geometry to ensure proper integration and functionality within the system.

Cost and Availability: Consider the cost-effectiveness of the magnet in relation to the desired performance. Evaluate the availability and cost of the magnet material, as well as any additional processing or customization required.

Manufacturing Feasibility: Assess the manufacturability of the magnet component, including the complexity of the desired shape, size, and magnetization pattern. Consider the feasibility and cost implications of manufacturing the magnet to the required specifications.

Mechanical Interactions: Evaluate the mechanical interactions of the magnet with other components in the system. Consider factors such as magnetic attraction or repulsion, mechanical stability, mounting requirements, and any potential impacts on the magnet's performance due to mechanical stress or vibrations.

英语

英语 日语

日语 德语

德语